Die Cutting Plywood Manufacturers In Dadar

Introduction

Indiana Plywood Industries is a shining example of quality and dependability in the crowded Dadar neighborhood of Mumbai when it comes to precise plywood manufacturing. Since our modest start in 1996, we have developed into one of the most reputable brands in the plywood sector, with a focus on die-cutting and a wide selection of block boards, waterproof furniture plywood, and calibrated plywoods.

Die-Cut Plywood: The Indiana Plywood Advantage

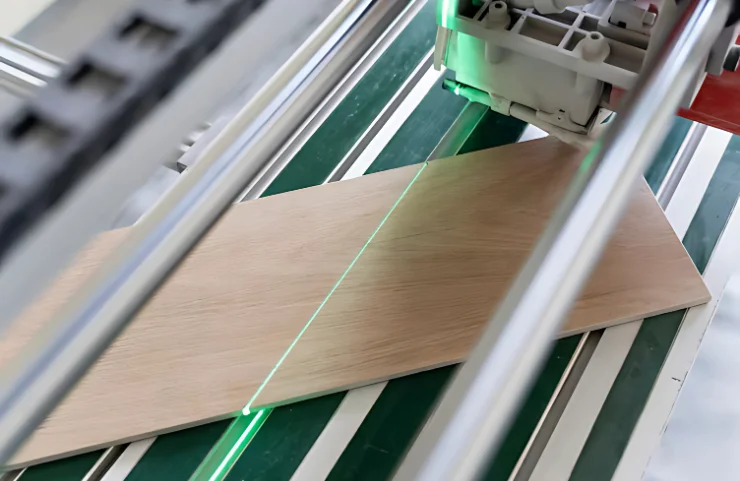

Die cutting plywood is a specialized manufacturing process that requires precision equipment and expertise. At Indiana Plywood, our Dadar facility combines traditional craftsmanship with modern technology to create custom-shaped plywood components that meet exacting specifications.

What Is Die-Cut Plywood?

Die-cut plywood is plywood that has been carefully cut with specialist die-cutting equipment into predetermined forms. Die cutting is perfect for industrial applications, decorative parts, and furniture components because it guarantees uniformity across several pieces, unlike traditional cutting techniques.

The process involves using sharp steel cutting dies pressed against plywood sheets with tremendous force, creating clean, precise cuts that would be difficult or impossible to achieve with manual cutting tools. This technique is particularly valuable when you need multiple identical pieces with complex shapes or curves.

The Growing Demand for Die-Cut Plywood

The Dadar neighborhood of Mumbai has long been a center for woodworking and furniture production. The need for precisely cut plywood components has increased dramatically as design trends and customer expectations have changed. Die-cutting experts are being used more and more by contractors, furniture makers, and interior designers to provide components that precisely match their ideas.

This is where the experience of Indiana Plywood is useful. With almost thirty years of expertise, we have honed our die-cutting techniques to produce outstanding quality that satisfies the various demands of our customers in Mumbai and beyond.

Indiana Plywood Industries: A Legacy of Excellence Since 1996

Our adventure started in 1996 with the straightforward goal of giving our customers the best plywood products available. As we commemorate more than 25 years in the business, it’s important to consider how we’ve changed while adhering to our basic principles.

Our Growth Story in Dadar’s Competitive Market

It was challenging to establish ourselves in Dadar’s cutthroat woodworking industry. The region has long been recognized for its abundance of plywood makers and suppliers. Indiana Plywood was unique because of our persistent dedication to quality and our readiness to spend money on specialized tools and training. While keeping our Dadar headquarters, we have grown our business throughout the years. Because to our advantageous position, which provides quick access to the city’s main commercial districts and transit networks, we are able to effectively service clients throughout Mumbai.

Indiana Plywood Difference: Quality, Consistency, and Service

What makes Indiana Plywood stand out among die-cutting plywood manufacturers in Dadar? It comes down to three core principles:

- Uncompromising Quality Control: Every sheet of plywood that enters our facility undergoes rigorous quality checks. We source our raw materials from sustainable suppliers and ensure that each finished product meets or exceeds industry standards.

- Precision and Consistency: Our investment in state-of-the-art die-cutting equipment ensures that every piece we produce is identical to the last. This consistency is crucial for furniture manufacturers and contractors who need components that fit perfectly every time.

- Customer-Centric Approach: We believe in building lasting relationships with our clients. This means understanding their specific needs, providing technical guidance, and delivering products on schedule.

Our Wide Selection of Products

To satisfy the wide range of demands of our clients, Indiana Plywood Industries provides a variety of plywood products. Each of these goods is improved by our die-cutting skills, which enable personalization that distinguishes our solutions.

Adjusted Plywoods: Accuracy in Each Sheet

It is made to precise thickness requirements, calibrated plywood is perfect for situations where accuracy is crucial. Our calibration procedure removes the variances that can happen during regular plywood manufacture and guarantees consistent thickness across the sheet.

This precision makes our calibrated plywood perfect for:

- Fine furniture manufacturing.

- Cabinet making.

- Architectural millwork.

- Precision engineering applications.

Our die-cutting service adds another dimension of precision to these already exacting products, allowing for complex shapes and designs that fit perfectly into larger assemblies.

Block Boards: Strength and Stability Combined

Block boards consist of a core of wooden strips sandwiched between veneers. This construction provides exceptional strength and stability, making block boards ideal for applications that require load-bearing capacity.

Indiana Plywood’s block boards are known for their:

- Exceptional dimensional stability.

- Resistance to warping and bending.

- Superior screw-holding capacity.

- Even texture for finishing.

Our die-cutting capabilities allow us to transform these sturdy boards into components for furniture legs, tabletops, shelving supports, and other applications requiring both strength and precise shapes.

Decorative Plywood: Beauty Meets Functionality

Our decorative plywood options combine aesthetic appeal with the structural benefits of high-quality plywood. Available in various wood veneers and laminates, these products are perfect for visible applications where appearance matters as much as function.

The die-cutting process allows us to create decorative elements like:

- Ornamental panels.

- Designer cabinet doors.

- Decorative wall elements.

- Custom furniture components.

Waterproof Furniture Plywood: Durability for Demanding Environments

Wooden furniture can suffer from warping, delamination, and degradation over time due to moisture. With specially designed adhesives and treatments that offer remarkable moisture resistance, our waterproof furniture plywood takes on this problem head-on.

These products are ideal for:

- Kitchen and bathroom cabinetry.

- Outdoor furniture components.

- Marine applications.

- High-humidity environments.

When combined with our die-cutting expertise, waterproof plywood becomes even more versatile, allowing for custom shapes that maintain their integrity even in challenging conditions.

Die-Cutting Process at Indiana Plywood Industries

Understanding our die-cutting process helps clients appreciate the precision and care that goes into every piece we produce. Here’s a behind-the-scenes look at how we transform raw plywood sheets into precisely cut components.

Step 1: Material Selection and Preparation

Sourcing the right kind of plywood for the job is the first step in the procedure. This choice is influenced by various factors, including thickness, wood species, grade, and intended purpose. In order to comprehend the needs of our clients and suggest the best material, our staff works closely with them. After being chosen, the plywood sheets are quality-checked and ready for cutting. A clean, level surface for the die-cutting process and conditioning the material to the proper moisture content are two examples of this preparation.

Step 2: Die Design and Creation

In order to direct the die production process for unique forms, our design team produces accurate digital templates. These designs take into consideration things like the intended function of the final product, material qualities, and grain direction. The actual cutting dies are made of premium steel and have sharp edges for precise cuts. Because of the quality and uniformity of the final goods, these dies are precision-made instruments that frequently represent a substantial investment.

Step 3: Die-Cutting Operation

The prepared plywood sheet is placed exactly beneath the die in our hydraulic press to begin the actual cutting operation. By exerting immense pressure, the press pushes the die through the plywood to form the required shape. Carefully monitoring this process, our operators modify timing and pressure to get the best results possible for a variety of plywood thicknesses and types. This knowledge is one of the things that sets competent die-cutting companies apart from less seasoned ones.

Step 4: Finishing and Quality Control

After cutting, each piece undergoes finishing processes that might include edge sanding, surface preparation, or treatment with protective coatings. These steps ensure that the die-cut components are ready for their intended applications. Quality control is integrated throughout the process, with multiple inspection points to catch any deviations from specifications. Only pieces that meet our rigorous standards leave our facility.

Applications of Die-Cut Plywood in Modern Manufacturing

The versatility of die-cut plywood makes it valuable across numerous industries and applications. Here are some of the ways our products find use in today’s market:

Furniture Manufacturing

Perhaps the biggest market for die-cut plywood components is the furniture sector. Die-cut components allow for designs that would be challenging or impossible to accomplish with conventional cutting techniques, such as curved chair backs and decorative table legs. Manufacturers in Dadar’s furniture industry appreciate die-cut components’ accuracy and consistency, which guarantee seamless assembly procedures and precisely designed final products.

Interior Design Elements

Custom timber pieces are becoming more and more common in interior design projects. Die-cut plywood makes it possible to create room separators, decorative wall panels, ceiling accents, and other components that give rooms character and warmth. Because of die-cutting’s accuracy, these components can precisely fit together or complement other design aspects to produce unified visual statements throughout an area.

Packaging Solutions

High-end products often come in custom wooden packaging that enhances the unboxing experience. Die-cut plywood creates precise packaging components that protect contents while conveying a sense of quality and attention to detail.

Industrial Applications

Beyond consumer products, die-cut plywood finds use in various industrial applications:

- Templates and jigs for manufacturing processes.

- Component parts for machinery and equipment.

- Specialized containers for sensitive equipment.

- Sound dampening elements in acoustic applications.

Architectural Models and Prototypes

Architects and product designers use die-cut plywood for creating precise models and prototypes. The ability to produce multiple identical pieces quickly makes iterative design processes more efficient.

Why Choose Indiana Plywood for Die-Cutting Services in Dadar?

Given the abundance of plywood producers in the Dadar region, why is Indiana Plywood Industries the go-to option for die-cutting services? We have many benefits than merely high-quality products.

Technological Edge

By investing in the newest die-cutting equipment, we are able to attain precision levels that beyond industry norms. Our equipment’s adaptability in handling different plywood types and thicknesses serves our wide range of clients.

Experienced Team

Die cutting is as much art as science. Our production team includes professionals with decades of experience who understand the nuances of working with different wood types and achieving optimal results even with challenging designs.

Customization Capabilities

Unlike manufacturers who offer only standard sizes and shapes, Indiana Plywood excels at customization. We work with clients to understand their specific requirements and create solutions that address unique challenges.

Sustainable Practices

We recognize the significance of environmental stewardship in the wood products sector. Sustainable forestry is a key component of our sourcing strategies, and we optimize materials and carefully design our production processes to reduce waste.

Understanding Plywood Quality

It might be difficult for people who are new to buying plywood products to comprehend quality considerations. When assessing die-cut plywood, keep the following in mind:

Core Construction

The stability and strength of plywood are determined by its inner layers. High-quality plywood has uniformly thick cores with few voids. In order to guarantee structural integrity in each sheet, we at Indiana Plywood carefully choose our core components.

Adhesive Quality

The strength and resistance to moisture of plywood are greatly influenced by the adhesives used to join its layers. Using unique water-resistant adhesives, our waterproof furniture plywood keeps its bond even in extremely humid conditions.

Surface Veneer

The outer veneer determines both appearance and how well the plywood will accept finishes. We offer various veneer options, from utilitarian to decorative, each selected for its specific characteristics and appearance.

Edge Quality After Cutting

The borders of cut pieces are one place where die-cutting quality is instantly noticeable. Clean edges with little ripping or splintering are the result of high-quality die cutting. Our meticulously calibrated cutting procedures and precision dies provide flawless edges that need little extra finishing.

Consistency Across Batches

Consistency across batches is essential for producers making several units of the same design. Pieces made weeks or months apart will have the same size and features thanks to our quality control procedures.

Future of Die-Cut Plywood in Manufacturing Sectors

As we look to the future, several trends are shaping the die-cut plywood market in Mumbai and beyond:

Integration with Digital Design

New opportunities for die-cut plywood are being created by the development of CNC manufacturing and digital design tools. With the assurance that their digital ideas can be turned into tangible parts by contemporary die-cutting machinery, designers may now produce ever-more-complex designs.

Sustainable Materials and Processes

Environmental concerns are driving interest in sustainably sourced wood products and manufacturing processes that minimize waste. Die cutting’s precision helps optimize material use, reducing the environmental footprint of plywood products.

Hybrid Materials

Innovative combinations of plywood with other materials like metals, composites, and recycled products are opening new design possibilities. Die cutting facilitates these combinations by creating precise interfaces between different materials.

Customization at Scale

Market trends favor personalized products, but traditional manufacturing struggles to deliver customization efficiently. Die cutting bridges this gap, allowing for customized designs that can still be produced with the efficiency needed for commercial viability.

FAQs About Peva Synchronized Plywood Manufacturers

Q1: What is the minimum order quantity for custom die-cut pieces?

Ans: This depends on the complexity of the design and the setup requirements. For simple shapes, we can accommodate orders as small as 50 pieces, while more complex designs may require minimum orders of 100-200 pieces to offset die creation costs.

Q2: Can you die-cut very thick plywood?

Ans: Our standard equipment handles plywood up to 25mm thick. For thicker materials, we may recommend alternative approaches or specialized equipment.

Q.3: Where can I buy Die Cutting Plywood In Dadar?

Ans. Directing users to Indiana Plywood Industries’ contact details: Visit indianaplywood.com or call +919892210648.

Conclusion

Indiana Plywood Industries is a reputable die-cut plywood producer in Dadar that blends traditional woodworking skills with contemporary manufacturing accuracy. Quality, dependability, and customer service have been the cornerstones of our reputation since 1996, and they still serve as the foundation for our business today. Whether you’re a constructor in need of accurate plywood pieces for a particular application, an interior designer wanting unique decorative elements, or a furniture manufacturer seeking consistent components, our staff has the know-how and tools to suit your needs. We invite you to experience the Indiana Plywood. Reach out to them today at +919892210648 or visit indianaplywood.com to discover how they can meet your needs with excellence and precision.

“Don’t forget to share this post!”